Ledden actuator Hydrostatic Valve Operators

|

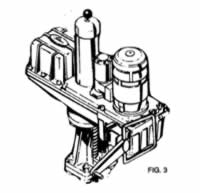

LHE SERIES The Ledeen LHE Series Operators utilize a full range of electric motor drives providing a wide selection of torques and speeds. Interlocked reversing starter assemblies are available either integrally or separate in explosion proof or weatherproof rated housings. Pushbuttons and indicator lights are also available. Other optional electrical accessories are available for specific application requirements. |

|

|

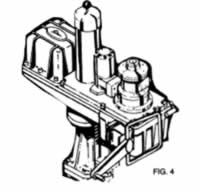

LHP SERIES The Ledeen LHP Series Operator is mechanically interchangeable with the LHE and utilizes air or gas as its primary power source. A variety of motor/transmission combinations offers a full range of torque and speed outputs. Standard pneumatic control packages are integrally mounted and piped on the operator thereby simplifying field installation. These packages range from simple manual control to complex computer or telemetrically signalled control for use in process systems. |

|

|

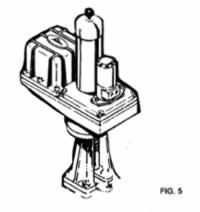

LHH SERIES_ The Ledeen LHH Series Operator is a modular unit designed for use with either a central hydraulic system or with an individual power unit. Close groupings of valves can be conveniently and economically powered from a central hydraulic supply. The LHH is compact and permits mounting in areas where space is an important factor. It is particularly desirable for service in normally inaccessible areas because the hydraulic supply may be located in a convenient location. |

|

|

THE HYDROSTATIC TRANSMISSION The Ledeen Hydrostatic Valve Actuator utilizes a proven hydrostatic transmission in which high torque levels are achieved by the controlled flow of high pressure fluid. It is this control of fluid pressure and flow which matches the Hydrostatic Figures 1 and 2 illustrate the positive displacement hydraulic motor and pump combination which distinguishes the hydrostatic transmission. It is the positive displacement characteristic of these tomponents which provides the name"Hydrostatic." The ratio of torque input and torque output remains essentially a fixed ratio throughout a wide speed range. In this relationship, torque output varies directly and only with hydraulic pressure level. This characteristic is maintained even at zero RPM and with the hydraulic fluid at rest, thus producing maximum torques with a minimum of hydraulic slippage. Figure 1 shows the basic Hydrostatic transmission schematically operating a linear type valve. Figure 2 illustrates the application of this transmission to a handwheel mechanism on

|

FEATURES COMPLETE UNITS FOR All VALVES The Ledeen Hydrostatic Actuator will motorize and control almost any type of line valve. It produces torque and RPM for direct application to the thrust nut or handwheel shaft. The unit includes necessary electrical and pneumatic controls and also a provision for auxiliary manual operation. BROAD TORQUE RANGE In the LH-5 series, sustained torque application up to 6000 inch pounds to the valve stem or drive nut at speeds varying from 10 to 140 RPM offer great application versatility. Larger Hydrostatic Valve Operators produce up to 150,000 inch pounds torque. RUGGED CONSTRUCTION Rugged construction of Hydrostatic components assures long, troublefree life. Permanently lubricated parts assure reliable, low maintenance operation. EASE OF INSTALLATION The actuator is adaptable for mounting on new or existing valves. Installation on existing valves can be accomplished without disturbing piping or manifolds. No special tools are needed. EFFICIENT AND ECONOMICAL OPERATION Simple, effective, low cost actuators permit power operation of existing valves while utilizing the most economical source of power available-electric, pneumatic or hydraulic. AUXILIARY MANUAL OPEf!ATION Auxiliary rotary handpump operation is provided on all units. The auxiliary rotary handpump is in the circuit at all times and does not have to be disengaged or re-engaged to make its use safe. VERSATILE CONTROLS Actuators can be equipped with a range of controls from simple manual operation to complex systems capable of accepting a variety of supervisory signals including position annunciation, intermediate incremental positioning, and other computer compatible functions. Actuators may be furnished with a wide variety of standard switchpacks featuring simple and individual adjustment of up to 16 limit switches. Standard motor control modules are also available. SAFETY FEATURES The hydraulic system is completely sealed. There is no possibility for atmospheric contamination. A variety of hydraulic flllids can be used for service in differing environmental conditions including operation in fire or explosive areas. BUILT-IN VALVE PROTECTION Easily adjustable and measurable torque output gives positive assurance that the load will be delivered accurately and that the valve structure will not be overstressed. The Hydrostatic transmission eliminates impact on the valve, as well as the need for any mechanical torque limiting mechanisms. Delivery of immediate maximum torque to the valve eliminates need for hammer blow thereby avoiding possible damaging action to the structure. |

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: