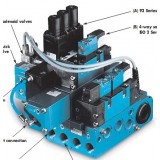

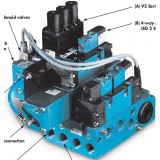

MAC proportional pressure control PQE and pressure control system

| Series | PQE6500 info | PQE92 info |

| Flow Cv | 6.3 | 1.3 |

| Port Size | 1/2-3/4" | 1/4-3/8" |

| Series | Proportional Multi-Pressure Pak info | Multi-Pressure Pak info |

OPERATIONALBENEFITS

1. Reliable operation, using two MAC 35 Series

2. Repeatability.

3. Fast response.

4. Long life.

5. High flow.

6. Low power consumption.

7. Not affected by vibrations.

8. Accurate pressure control.

9. Analog command signal and output.

GENERALDATA

Ambient temperature :32 to 120°,F/0 to 50°

Vibration :Not affected

Port size :1/8°±

Connector :4 pin terminal block

Mounting :Any plane

ELECTRICALDATA

Supply voltage :18 to 28 VDC

Supply current :50 to 350mA

Command signal :4 to 20mA, 0-10v

Command type :Differential

Input impedance :316 °0.1% (current4.99 °1.0% (voltage

EMI/RFI protection :Common mode and high frequency noise reduction

PNEUMATICDATA

Inlet pressure :120 PSI max (for 10-100 PSI output pressure)

8 BAR max (for 0.66-6.6 BAR output pressure)

Fluids :Air or inert gases

Lubrication :Not required, if used select a medium aniline point oil

Output pressure :

0 to 10, 30, 40, 45, 60 and 100

0 to 0.66, 2, 2.6, 3, 4 and 6.6

Overall accuracy :

1.5% full scal

2.5% full scal

Flow :Cv 0.10/100 Nl/min

Minimum closed end volume :1.0 cubic inch

OPERATIONALBENEFITS

1. Fast response.applications.

2. Long life.

3. High flow.

4. The use of a digital command signal brings easy installation and use.

5. A compact and lightweight unit saves room and installation costs.

6. This system is the alternative to proportional valves if more than six pressures or closed loop feedback are not required. is easy to set up and

7. The Multi-Pressure Pakmaintain.

8. For 2, 3 or 4 ported weld guns and other

9. Accuracy of °?2.5 % of full scal

TECHNICALDATA

Min. supply pressure :25 PSI (1.7 BAR)

Max. supply pressure :150 PSI (10 BAR)

Pressure output range :25-120 PSI (1.7 to 8 BAR)

Voltages available AC :120/60, 110/50

DC :12 & 24 volt. 1.8 to 12.7 watts

Other AC and DC

Consult factory

voltages available :

Air supply :40 micron filtration

Lubrication :Not required but if lubrication is used, a medium aniline point oil is recommended

NOTE: Pressures shown are minimum and maximum safe working pressures.

*Series Port size Flow

82 1/4" - 3/8" C 0.9 / 900 Nl/Min

v

93 3/8" - 1/2" C 2.4 / 2400 Nl/Min

v

6300 3/8" - 1/2" C 2.1 / 2100 Nl/Min

v

6500 1/2" - 3/4" C 3.5 / 3500 Nl/Min

v

ISO 1 1/4" - 3/8

AMS ¨C NALOG MONITOR SIGNAL

- 0-10 VDC FEEDBACKSIGNALTHATPROVIDESAVOLTAGE

PROPORTIONALTOTHEOUTPUTPRESSURE

LMS 1 ¨C OGIC MONITOR SIGNAL

- 5 VDC (TTL HIGH), 24 VDC (HIGH), 5 VDC (LOW),OR 24 VDC (LOW)

!

GO/ NOGO! FEEDBACKSIGNAL (DEPENDINGONREQUIREMENTS)

LMS 2 ¨C

OGIC MONITOR SIGNAL

- 5 VDC (TTL LOW), 24 VDC (HIGH),OR 24 VDC (LOW) !GO / NOGO

FEEDBACKSIGNAL

(DEPENDINGONREQUIREMENTS)

CV+ - P

OSITIVE COMMAND SIGNAL

- POSITIVELEADFORTHE 0 ¨C 10 VDCOR 4-20MACOMMANDSIGNAL

(DEPENDSONREQUIREMENTS)

CV- - N

EGATIVE COMMAND SIGNAL

- NEGATIVELEADFORTHE 0 ¨C 10 VDCOR 4 ¨C20MACOMMANDSIGNAL

(DEPENDSONREQUIREMENTS)

C

OM ¨C AIN POWER COMMON

- COMMONLEADFORTHE 24 VDC POWER

PWR ¨C AIN POWER

- POSITIVE LEADFORTHE 24 VDC POWER

OPERATIONALBENEFITS

1. Reliable operation, using two MAC 34 Series

with balanced poppet.

2. Fast response.

3. Long life.

4. High flow.

5. Low power consumption.

6. Not affected by vibrations.

7. Accurate pressure control.

8. Analog command signal and output.

GENERALDATA

Ambient temperature :32 to 120°,F/0 to 50°

LED indicators :Red : power on - Green : pressure achieved

Vibration :Not affected

Port size :G 1/8°±, 1/8°± NPT - Option : bottom por

Connector :7 pin terminal block

Mounting :Any plane

ELECTRICALDATA

Supply voltage :20.4 to 26.4 VDC

Supply current :50 to 275mA

Command signal :0 to 10V or 4 to 20mA

Command type :Single-ended or differential

Input impedance :4.99 k °1.0% (voltage316 °?0.1% (current

Analog Monitor Signal (AMS) :0 to 10 Volt

Logic Monitor Signal (LMS) :2 types of signals (see How to order) (sinking)

EMI/RFI protection :Common mode and high frequency noise reduction for electrical inputs

PNEUMATICDATA

Inlet pressure* :

120 PSI max (for 10-100 PSI output pres.)

8 BAR max (for 0.66-6.6 BAR output pres.)

Fluids :Compressed air or inert gases

Lubrication :Not required. However, if used, a medium aniline point oil is

OPERATIONALBENEFITS

1. Reliable operation, using two MAC 45 Series

with balanced poppet.

2. Fast response.

3. Long life.

4. High flow.

5. Low power consumption.

6. Not affected by vibrations.

7. Accurate pressure control.

8. Analog command signal and output.

GENERALDATA

Ambient temperature :32 to 120F/0 to 50

LED indicators :Red : power on - Green : pressure achieved

Vibration :Not affected

Port size :G 1/8±, 1/8± NPT - Option : bottom por

Connector :7 pin terminal block

Mounting :Any plane

ELECTRICALDATA

Supply voltage :20.4 to 26.4 VDC

Supply current :50 to 350mA

Command signal :0 to 10V or 4 to 20mA

Command type :Single-ended or differential

Input impedance :4.99 k 1.0% (voltage316 0.1% (current

Analog Monitor Signal (AMS) :0 to 10 Volt

Logic Monitor Signal (LMS) :2 types of signals (see How to order) (sinking)

EMI/RFI protection :Common mode and high frequency noise reduction for electrical inputs

PNEUMATICDATA

Inlet pressure* :

120 PSI max (for 10-100 PSI output pres.)

8 BAR max (for 0.66-6.6 BAR output pres.)

Fluids :Compressed air or inert gases

Lubrication :Not required. However, if used, a medium aniline point oilis recommended

O

OPERATIONALBENEFITS

1. Reliable operation, using two MAC 45 Series

with balanced poppet.

2. Fast response.

3. Long life.

4. High flow.

5. Low power consumption.

6. Not affected by vibrations.

7. Accurate pressure control.

8. Analog command signal and output.

GENERALDATA

Ambient temperature :32 to 120F/0 to 50

LED indicators :Red : power on - Green : pressure achieved

Enclosure :Aluminium Barstock, sealed

Vibration :Not affected

Port size :1/8± (side only

Connector :3, 5, 6 or 7 Pin Plug-in or 7 wire grommet

Mounting :Any plane

Washdown :Standard

ELECTRICALDATA

Supply voltage :20.4 to 26.4 VDC

Supply current :50 to 350mA

Command signal :0 to 10V or 4 to 20mA

Command type :Single-ended or differential

Input impedance :4.99 k 1.0% (voltage 316 0.1% (current

Analog Monitor Signal (AMS) :0 to 10 Volt

Logic Monitor Signal (LMS) :2 types of signals (see How to order) (sinking)

EMI/RFI protection :Common mode and high frequency noise reduction for electrical inputs

PNEUMATICDATA

Inlet pressure* :120 PSI max (for 10-100 PSI output pres.),8 BAR max (for 0.66-6.6 BAR output pres.)

Fluids :Compressed air or inert gases

Lubrication :Not required. Howev

OPERATIONALBENEFITS

1. Reliable operation, using two MAC 34 Series

with balanced poppet.

2. Fast response.

3. Long life.

4. High flow.

5. Low power consumption.

6. Rugged enclosure.

7. Not affected by vibrations.

8. Accurate pressure control.

9. Can be stand alone or used in combination

with our remote air sandwich regulators.

10. Analog command signal and output.

GENERALDATA

Ambient temperature :32°,F to 120°,F/0 to 50

LED indicators :Red : power on - Green : pressure achieved

Enclosure :Aluminium, sealed

Vibration :Not affected

Port size :G 1/8°±, 1/8°± NPT - Option : bottom por Micro or mini 3, 5 or 6 pin plug-in

Connector :3, 4, 5 or 6 wire grommet

Mounting :Any plane

Protection :IP 65

ELECTRICALDATA

Supply voltage :20.4 to 26.4 VDC

Supply current :50 to 275mA (single transducer), 50 to 500mA (dual transducer)

Command signal :0 to 10V or 4 to 20mA

Command type :Single-ended or differential

Input impedance :4.99 k °1.0% (voltage, 316 °?0.1% (current

Analog Monitor Signal (AMS) :0 to 10 Volts

Logic Monitor Signal (LMS) :TTL or 24V 10mA max. (sinking)

EMI/RFI protection :Common mode and high frequency noise reduction for electrical inputs

1 Type

A Analog

2 Mounting / Port Size & Type

AA Base Side Port 1/8!± NPT

AB Base Side Port 1/8!± BSPP

AC Base Side Port 1/8!± BSPT

AD Base Side 10/32

AE Base Side Port M5

AF Base Side M4 Tube Receptacle

AG Base Side 5/32 Tube Receptacle

CA* Base Manifold Mt.

DA DIN Rail Base 1/8!± NPTF Side Por

DB DIN Rail Base 1/8!± BSPPL Side Por

DC DIN Rail Base 1/8!± BSPTR Side Por

DD DIN Rail Base 10/32 Side Port

DE DIN Rail Base M5 Side Port

DF DIN Rail Base M4 Tube Receptacle

DG DIN Rail Base 5/32 Tube Receptacle

3 Pressure Range

0A 100 psi

0B 60 psi

0C 30 psi

0D 15 psi

0N 10 psi

0T 45 psi

0J 75psi

0L 4 psi

4 Pressure Reference

G Gage Pressure

5 Accuracy

A !à 1.5% F.S

C !à 0.5% F.S

E !à 2.5% F.S

6 Command Signal

B 0 - 10v Differential

D 4 - 20mA Differential

7 LMS Signal

A TTL LMS & AMS

8 Cover

A No Cover

1 Spacing

00 29.00mm Spacing

A Side Cylinder Ports

3 Style

A Standard

4 Port Size and Thread Type

A 1/8!± NPT

B 1

OPERATIONOFTHEPQE

1. The pilot operated regulator and the PPC5C are both fed from a common inlet.

2. The °∞out°± port of the PPC5C sends pressure to the pilot port of the pilot operated regulator and to the °∞12°±

of the 400 Series Quick Exhaust Valve. The secondary pressure of the pilot operated regulator is sent to the

output port of the block and it is also sent to the °∞14°± end and inlet of the 400 Series Quick Exhaust Valv

3. The outlet pressure of the PPC5C along with the memory spring in the 400 Series valve will keep the valve in a

closed state as the unit increases pressure.

4. To reduce pressure, drop the PPC5C°Os signal. This will lower the pressure on the °∞12°± end of the 400 Ser

valve. The °∞14°± end of the 400 Series valve now has higher pressure causing a snap-action shifting of the 4

Series valve which will quickly exhaust the downstream pressure to the new selected pressure.

PNEUMATICDATA

Inlet pressure :120 PSI max

Fluids :Air or inert gases

Lubrication :Not required. However, if used, a medium aniline point oilis recommended

Filtration :40 micron

*Output pressure :20 to 100 PSI

Overall accuracy :2.5% full scale

All ports :1/2, 3/4, NPTF, BSPP

OPERATIONOFTHEPQE

1. The pilot operated regulator and the PPC5C are both fed from a common inlet.

2. The °∞out°± port of the PPC5C sends pressure to the pilot port of the pilot operated regulator and to the °∞12°±

of the 400 Series Quick Exhaust Valve. The secondary pressure of the pilot operated regulator is sent to the

output port of the block and it is also sent to the °∞14°± end and inlet of the 400 Series Quick Exhaust Valv

3. The outlet pressure of the PPC5C along with the memory spring in the 400 Series valve will keep the valve in a

closed state as the unit increases pressure.

4. To reduce pressure, drop the PPC5C°Os signal. This will lower the pressure on the °∞12°± end of the 400 Ser

valve. The °∞14°± end of the 400 Series valve now has higher pressure causing a snap-action shifting of the 4

Series valve which will quickly exhaust the downstream pressure to the new selected pressure.

OPERATIONALBENEFITS

1. Accurate pressure control.

2. Fast response.

3. High flow.

4. Quick exhaust function.

5. Unaffected by change in line pressure.

6. Long life.

7. Designed to meet Nema 4 specifications.

8. Analog control.

9. Analog or TTL feedback.

10. Closed loop s

OPERATIONALBENEFITS

1. Fast response. 8. For 2, 3 or 4 ported weld guns and other

2. Long life. applications.

3. High flow. 9. Accuracy of °?2.5 % of full scale (consult factor

4. The use of an analog or 4 bit or 8 bit command for other accuracies).

signal brings increased accuracy in pressure 10. DeviceNet compatible.

control.

5. A compact unit saves room and installation

costs.

6. The analog and logic (TTL) outputs allow

for constant pressure monitoring from

the control unit.

7. Infinite or discrete number of pressures

available.

TECHNICALDATA

Supply pressure :

2 to 10 bar/30 to 150 PSI

*Output pressure :

Standard : 1.7 to 10 bar, other ranges upon request.

25 to 150 PSI

* For 82 and ISO 1 - 1.7 to 8 BAR, 25 to 120 PSI

*Series Port size Flow

82 1/4" - 3/8" C 0.9 / 900 Nl/Min

v

93 3/8" - 1/2" C 2.4 / 2400 Nl/Min

v

6300 3/8" - 1/2" C 2.1 / 2100 Nl/Min

v

6500 1/2" - 3/4" C 3.5 / 3500 Nl/Min

v

ISO 1 1/4" - 3/8" C 1.1 / 1100 Nl/Min

v

ISO 2 3/8" - 1/2" C 2.1 / 2100 Nl/Min

v

ISO 3 1/2" - 3/4" C 5.0 / 5000 Nl/Min

v

OPERATIONALBENEFITS

1. Accurate pressure control.

2. Fast response.

3. High flow.

4. Quick exhaust function.

5. Unaffected by change in line pressure.

6. Long life.

7. Designed to meet Nema 4 specifications.

8. Analog control.

9. Analog or TTL feedback.

10. Closed loop system.

PPCTYPE

Analog, single transducer external sense, bottom O-ring mount

ELECTRICALDATA

Reference PPC5Cspecifications

PHYSICALDATA

Connector :Reference PPC5Cspecifications

Enclosure :Aluminum, sealed

Mounting :Any plane

Ambient temperature range :0 to 50C (32F to 120

PNEUMATICDATA

Inlet pressure :120 PSI max

Fluids :Air or inert gases

Lubrication :Not required. However, if used, a medium aniline point oil is recommended

Filtration :40 micron

*Output pressure :20 to 100 PSI

Overall accuracy :2.5% full scale

All ports :1/2, 3/4, NPTF, BSPPL, BSPTR

Flows :

Output flow :

1/2± ports: Cv 5.33/4± ports: Cv 6

Exhaust flow :

1/2± ports: Cv 1.53/4± ports: Cv 1

**Output volume requirements :Port sizeOutput volume atMinimum length end of output pipeof output pipe 1/2±100 Cu. in. and larger78 50 to 99 Cu. in.100 3/4±100 Cu. in. and larger60 50 to 99 Cu. in.90

* The quick exhaust portion

OPERATIONALBENEFITS

1. Fast response.

applications.

2. Long life.

3. High flow.

4. The use of a digital command signal brings

easy installation and use.

5. A compact and lightweight unit saves room

and installation costs.

6. This system is the alternative to proportional

valves if more than six pressures or closed

loop feedback are not required.

7. The Multi-Pressure Pak

is easy to set up and

maintain.

8. For 2, 3 or 4 ported weld guns and other

9. Accuracy of 2.5 % of full scal

TECHNICALDATA

Min. supply pressure :

25 PSI (1.7 BAR)

Max. supply pressure :

150 PSI (10 BAR)

Pressure output range :

25-120 PSI (1.7 to 8 BAR)

Voltages available AC :

120/60, 110/50

DC :

12 & 24 volt. 1.8 to 12.7 watts

Other AC and DC

Consult factory

voltages available :

Air supply :

40 micron filtration

Lubrication :

Not required but if lubrication is used, a medium aniline point oil is recommended

NOTE: Pressures shown are minimum and maximum safe working pressures.

*Series Port size Flow

82 1/4" - 3/8" C 0.9 / 900 Nl/Min

v

93 3/8" - 1/2" C 2.4 / 2400 Nl/Min

v

6300 3/8" - 1/2" C 2.1 / 2100 Nl/Min

v

6500 1/2" - 3/4" C 3.5 / 3500 Nl/Min

OPERATIONALBENEFITS

1. Fast response.

2. Long life.

applications.

3. High flow.

4. The use of an analog or 4 bit or 8 bit command

for other accuracies).

signal brings increased accuracy in pressure

10. DeviceNet compatible.

control.

5. A compact unit saves room and installation

costs.

6. The analog and logic (TTL) outputs allow

for constant pressure monitoring from

the control unit.

7. Infinite or discrete number of pressures

available.

8. For 2, 3 or 4 ported weld guns and other

9. Accuracy of 2.5 % of full scale (consult factor

TECHNICALDATA

Supply pressure :

2 to 10 bar/30 to 150 PSI

*Output pressure :

Standard : 1.7 to 10 bar, other ranges upon request.

25 to 150 PSI

* For 82 and ISO 1 - 1.7 to 8 BAR, 25 to 120 PSI

*Series Port size Flow

82 1/4" - 3/8" C 0.9 / 900 Nl/Min

v

93 3/8" - 1/2" C 2.4 / 2400 Nl/Min

v

6300 3/8" - 1/2" C 2.1 / 2100 Nl/Min

v

6500 1/2" - 3/4" C 3.5 / 3500 Nl/Min

v

ISO 1 1/4" - 3/8" C 1.1 / 1100 Nl/Min

v

ISO 2 3/8" - 1/2" C 2.1 / 2100 Nl/Min

v

ISO 3 1/2" - 3/4" C 5.0 / 5000 Nl/Min

v

OPERATIONALBENEFITS

1. Accurate pressure control.

2. Fast response.

3. High flow.

4. Quick exhaust function.

5. Unaffected by change in line pressure.

6. Long life.

7. Designed to meet Nema 4 specifications.

8. Analog control.

9. Analog or TTL feedback.

10. Closed loop system.

PPCTYPE

Analog, single transducer external sense, bottom O-ring mount

ELECTRICALDATA

Reference PPC5Cspecifications

PHYSICALDATA

Connector :Reference PPC5Cspecifications

Enclosure :Aluminum, sealed

Mounting :Any plane

Ambient temperature range :0 to 50C (32F to 120

PNEUMATICDATA

Inlet pressure :120 PSI max

Fluids :Air or inert gases

Lubrication :Not required. However, if used, a medium aniline point oil is recommended

Filtration :40 micron

*Output pressure :20 to 100 PSI

Overall accuracy :2.5% full scale

All ports :1/4, 3/8, NPTF, BSPPL, BSPTR

Flows :Output flow :1/4± ports: Cv 0.943/8± ports: Cv 1

Exhaust flow :1/4± ports: Cv 1.33/8± ports: Cv 1

**Output volume requirements :Port sizeOutput volume atMinimum length end of output pipeof output pipe 1/4±100 Cu. in. and larger12 50 to 99 Cu. in.50 3/8±100 Cu. in. and larger 24 50 to 99 Cu. in.50

* The quick exhaust portion of th