Honeywell pressure transmitter

ST 700 Gauge Pressure Transmitters (STG700) are ideal for applications ranging from high-pressure measurements in boilers and fuel feeds to tank level measurement applications with a relatively high process temperature. Users have the option of choosing between dual-head and in-line models to match their process interface requirements.

Dual Head Gauge Pressure Transmitters are suited for typical applications involving reaction vessels in the chemical industry and level applications with process temperatures up to 257°F /125°C.

In-Line transmitters are screwed directly onto a 1/2” male NPT nipple and can be installed in hazardous environments for accurate, repeatable pressure measurement. Typical applications include high-pressure measurement in boilers, fuel feeds and high-pressure reaction vessels in the petrochemical and hydrocarbon recovery industries.

The following models are available for deployment:

• STG740/STG74L 0-500 psi

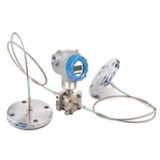

ST 700 Remote Diaphragm Seal Transmitters (STR700) provide accurate measurement in a wide variety of applications involving corrosive or high temperature process fluids. Typical applications include level measurement in pressurized vessels in hydrocarbon processing and flow measurement of slurries and high viscosity process fluids in chemical plants.

Honeywell offers the following STR700 Remote Diaphragm Seal Transmitters:

Flush flange seals

Flange seal with extended diaphragm

Pancake seals

Sanitary seals

Chemical tee “taylor” wedge

Seals with threaded process connections

Saddle seals

Calibration rings

Stainless steel armor and pvc coated stainless steel armor capillaries

2” Stainless steel nipples

Welded meter body

Two models are available with the following range and span limits:

STR73D -100 to 100 psid (-7 to 7 bar) 1 to 100 psid (0.07 to 7 bar)

STR74G &nb

Honeywell’s STT 3000® Smart Temperature Transmitter portfolio helps process manufacturers, Original Equipment Manufacturers (OEMs) and Engineering Procurement Construction (EPC) contractors with reliable, accurate and stable temperature measurements across monitoring, control and safety applications. It is offered as a three-tiered solution, providing the right mix of price and performance to meet varied process application needs.

STT3000 Smart Temperature Transmitters can be used in various scenarios:

When used with critical rotating and static temperature equipments, STT 3000 helps monitor and protect the health of assets.

When used to monitor the temperature of emissions from stacks, it helps meet and comply with environmental regulations.

When used in process heating and cooling applications, STT 3000 helps reduce energy waste and increase throughput. When deployed in process applications connected with safety shutdown, it can enhance the overall safety and reduce risk.

When used between production and consumption points, it helps measure energy content and reduce variations.

STT 3000 Smart Temperature Transmitters are available in

STT170 is a measurement solution for temperature monitoring applications. It helps end users and Original Equipment Manufacturers (OEMs) achieve reliable and accurate temperature measurement in a cost-effective manner.

The STT170 is Honeywell’s economy-tier family of temperature transmitters to flank the existing mid-tier STT250 and high-tier STT350 temperature transmitters. It helps convert low level signals from temperature sensors such as RTDs and TCs into current signals and is capable of transmitting long distances through noisy plant environments. The STT170 line consists of four temperature transmitters and one configuration tool:

STT171 – Analog output, RTD-only sensor input

STT173 – Analog output, RTD or thermocouple sensor input

STT17H – HART output, RTD & thermocouple sensor input

STT17F – FOUNDATION Fieldbus protocol, RTD & thermocouple sensor input

STT17C – PC-based configuration tool for configuring the STT171, STT173 and STT17H transmitters

Honeywell’s STT250 is ideal for temperature measurement across a broad range of control and safety applications. It is targeted at the mid-tier temperature measurement market offering excellent performance and features at a low installed cost.

STT250 Smart temperature transmitters are used to monitor and control temperature of critical rotating and static assets thereby enhancing equipment health and performance. In several process heating applications, these are employed to control process temperatures leading to energy efficiency and product quality.

STT250 converts low level inputs from a variety of temperature sensors such as RTDs/TCs into current output and is capable of transmission over long distances through noisy plant environments. STT250 is available in different forms - as a module, capable of getting into a temperature sensor head or Mounted in the DIN Rail panel or Field Mounted on a two inch pipe. These units come with several communication options which include 4 to 20ma analog output, HART Protocol Version 5/6 and DE Protocol.

STT350 Smart Temperature Transmitter is Honeywell’s high performance offering for critical control and high accuracy temperature measurement applications that involve fiscal metering. It ensures high stability and accurate temperature measurement in flow applications thereby offering significant cost savings for energy suppliers and consumers.

STT350 Temperature Transmitter converts low level signals from temperature sensors into current signals capable of long distance transmission. In view of its unique design and robust galvanic isolation, the temperature measurement is immune to electromagnetic and RF interference, helping users measure temperature in noisy industrial environments as seen in mineral and metal industries. In addition, it helps users measure temperature accurately leading to improved energy efficiency and product quality.

STT350 is based on Honeywell DE protocol

STT35F is based on Foundation Fieldbus protocol

It is available in the field mounted, wall mounted and DIN Rail mounted versions.

Honeywell temperature probe assemblies are ideal for process manufacturers, Original Equipment Manufacturers (OEMs) and Engineering Procurement Construction (EPC) contractors for temperature measurement.

What Is It?

What is it

Temperature probe assemblies are installation-ready temperature measurement assemblies offered with any of Honeywell's temperature transmitters, sensor heads, sensors, thermowells and process connections. They are available in three versions-

STT820: Rigid probe assembly

STT830: Threaded and socket weld thermowell assembly

STT840: Drilled and flanged thermowell assembly

Temperature probes save users time in terms of engineering, ordering and installation/commissioning since these come in ready to install, fully calibrated assemblies with global agency approvals.

#content h2

{

margin: 0 0 0px !important;

}

How Does It Work?

How it works

Temperature probe assemblies are available

Effective flow measurement requires accurate and reliable flow calculation. Honeywell’s MVX 700 and 2000 OEM Multivariable Pressure Transducers help users gain precision in the flow measurement process by enhancing flow calculation accuracy and improving flow computer reliability.

MVX 700 and 2000 OEM Multivariable Pressure Transducers are based on Honeywell’s multivariable sensor technology. The transmitters measure both differential pressure and absolute pressure and eliminate the need for two separate transmitters or transducers integrated to flow computers or chart recorders. The multiple measurements carried out by the pressure transducer and the proven sensor characterization lower the overall costs for users.

Based on the proven piezoresistive sensor technology, the pressure transducer provides ±0.25% accuracy and stable readings for differential pressure and absolute pressure to improve product reliability and reduce zero drift for flow computers. The transmitter also contributes to increased flow accuracy for manufacturers of cost-effective flow computers.

Honeywell’s MVX 800 and 3000 OEM Multivariable Pressure Transducers are based on Honeywell ST 3000 and SMV 3000 sensor technology and enable an effective flow measurement process by enhancing flow calculation accuracy and improving the reliability of flow computers.

MVX 800 and 3000 OEM Multivariable Pressure Transducers measure both differential pressure and static pressure (absolute or gauge). Similar to MVX 700 and 2000, the transmitter eliminates the need for two separate transmitters or transducers integrated into flow computers. The multiple measurements carried out by the pressure transducer and the proven sensor characterization bring significant cost savings to users while enabling effective flow measurement. The transmitter transmits an output signal proportional to the measured variables in multiplexed pulse format for interfacing with the flow computers or RTUs.

The following models are available:

Differential Pressure: 0 to ±400 inH2O; 0 to ±1,000 mbar

Absolute Pressure or Gauge Pressure:

0 to 750 psia; 0 to 52 bara

0 to 1,500 psia; 0 to 103 bara

0 to 4,500 psig; 0 to 310 bara.

Honeywell’s SmartLine ST 700 Absolute Pressure Transmitters (STA700) are targeted at applications requiring robust performance in the vacuum range of pressure. This includes low-pressure measurement in vacuum distillation columns, where energy savings are directly proportional to the vacuum in the column.

The STA700 Absolute Pressure Transmitters are available in two variants – In-line (STA7XL) and Dual Head (STAXX) – in the following ranges:

STA722/STA72L 0 to 780 mmHgA (0 to 1,040 mbarA)

STA740/STA74L 0 to 500 psia (0 to 35 barA)

STA77L 0 to 3000psia (0 to 210 barA)

STA 700 transmitters offer the following compelling features:

Accuracy of up to 0.065% of span

Onboard pressure and temperature compensation

Alphanumeric display capabilities

External zero, span and configuration capability

Honeywell’s SmartLine ST 700 Pressure Transmitter family includes absolute pressure, gauge pressure, flange mount and remote seal transmitters that meet industry requirements in performance, stability, reliability and rangeability. With innovative modularity and an intuitive human machine interface (HMI), these products are ideal for a wide range of industrial process applications.

SmartLine ST 700 transmitters offer the following features:

Accuracy of up to 0.05%

Stability of 0.02% per year for five years

Modularity with field-replaceable units

Onboard pressure and temperature compensation

Alphanumeric display capability

External zero, span and configuration capability

100ms response time

Polarity-insensitive electrical connections.

SmartLine ST 700 transmitters provide self-diagnostics to help maintain high uptime, meet regulatory requirements, and attain high quality standards. In addition, their turndown ratio of 100:1 and modular design eliminates the need to stock transmitters wit

Honeywell’s SmartLine ST 800 Pressure Transmitter family includes absolute pressure, gauge pressure, draft range pressure, flanged and remote seal transmitters. Refineries, chemical and pharmaceutical plants and paper mills around the globe rely on these transmitters for accurate and consistent pressure measurement.

Want to see how SmartLine ST 800 Pressure Transmitters lead the industry in accuracy? Compare them with others in the market.

What Is It?

What is it

Pressure Transmitters for a Wide Range of Industrial Process Applications

SmartLine ST 800 pressure transmitters offer the following features:

Accuracy of up to 0.025%

Stability of 0.01% per year

Onboard pressure and temperature compensation

Modularity with field-replaceable units

Unequaled display capabilities

External zero, span and configuration capability

90ms response time

Polarity-insensitive electrical connections

Lifetime 15-year warranty

Effective control and monitoring of a process requires accurate and consistent measurement of different process variables. Honeywell’s SMV 3000 Smart Multivariable Flow Transmitter measures the flow of virtually any liquid, gas or slurry for which a primary flow element exists to provide a differential measurement and helps users improve product yield, process efficiency and plant safety.

The SMV 3000 Smart Multivariable Flow Transmitter combines integrated sensor and microprocessor technologies as well as dynamic flow compensation to produce the most accurate and consistent flow measurement. It comes in three different models -

SMA110 0 to 100 psia 0-1in/ 25 inH2O

SMA125 0 to 750 psia 0-1in / 400 inH2O

SMG170 &nb

Honeywell’s ST 3000 Series 100 Gauge Pressure Transmitters offer exceptional performance and are ideal for applications ranging from high-pressure measurements in boilers and fuel feeds to tank level measurement applications with a relatively high process temperature. Users have the option of choosing between dual-head and in-line models to match their process interface requirements.

What Is It?

What is it

The Dual-Head range of ST 3000 Series 100 Gauge Pressure Transmitters is suited for applications requiring small flange, small sanitary connections or 1/2” NPT. Typical applications include gauge pressure measurement of reaction vessels in the chemical industry and level applications with a process temperature of up to 302°F /150°C.

In-Line transmitters are screwed directly onto a 1/2” male NPT nipple and can be installed in hazardous environments for accurate, repeatable pressure measurement. Typical applications include high-pressure measurement in boilers, fuel feeds and high-pressure reaction vessels in the petrochemical and hydrocarbon recovery industries

The following models are available

Honeywell’s ST 3000 Series 100 Remote Diaphragm Seal Transmitters demonstrate proven reliability in applications with a wide variety of secondary fill fluids for corrosive or high temperature process fluids. Typical applications include high-accuracy level measurement in pressurized vessels in hydrocarbon processing and flow measurement of slurries and high viscosity process fluids in chemical plants.s

What Is It?

What is it

Honeywell offers the following ST 3000 Series 100 Remote Diaphragm Seal Transmitters:

Flush Flange Seals

Flange Seal with Extended Diaphragm

Pancake Seals

Sanitary Seals

Chemical Tee “Taylor” Wedge

Seals with Threaded Process Connections

Saddle Seals

Calibration Rings

Stainless Steel Armor and PVC Coated Stainless Steel Armor Capillaries

2” Stainless Steel Nipples

Welded Meter Body

Five transmitter series are available:

STR12D: &n